Oli mesin mengandung banyak aditif. Guna aditif ini macam macam. Mulai dari untuk mengurangi aus, untuk membersihkan mesin, mencegah penguapan dan lain lain. Yang menjadi perhatian adalah beberapa orang punya kebiasaan menambahkan aditif ke mesin dengan tujuan untuk menambah perlindungan. Mereknya macam macam, kebanyakan merek luar macam STP atau nano, namun ada juga merek dalam negeri.

Tujuannya bagus, tapi apa hasilnya juga dijamin bagus?

Menambah aditif anti aus tidak selalu menambah sifat anti aus

Dalam pembuktiannya, yang sering dipakai untuk mendemonstrasikan manfaat aditif oli adalah percobaan sifat anti aus dari oli, menguji perlindungan terhadap gesekan. Oli yang ditambah aditif diperlihatkan akan lebih sedikit ausnya daripada yang tidak pakai aditif.

Namun ternyata tidak semua oli akan makin baik perlindungannya terhadap aus setelah ditambah aditif anti aus. Ini bisa dilihat dari sharingan bro 540 RAT, yang telah melakukan percobaan pengecekan anti aus dari banyak sekali merek oli. Ada yang jadi lebih baik setelah ditambah aditif, ada yang lebih jelek setelah ditambah aditif.

Berikut kutipannya:

540 RAT – Tech Facts, NOT Myths

1. Prolong Engine Treatment added to 5W30 Pennzoil Ultra, API SN synthetic = 136,658 psi

This oil on its own WITHOUT the Prolong Engine Treatment added to it, has a wear protection capability of 92,569 psi. With the recommended amount of Prolong added per qt, its wear protection capability “WENT UP 48%”.5W30 Pennzoil Ultra, API SN synthetic: dari 92,569 psi “WENT UP 48%” jadi 136,658 psi

5W30 Castrol GTX, API SN conventional: dari 95,392 psi “WENT UP 37%” jadi 130,366 psi5W30 Pennzoil, API SN conventional (yellow bottle): dari 76,989 psi “WENT UP 52%” jadi 117,028 psi dengan “recommended amount of Prolong”.

5W30 Pennzoil, API SN conventional (yellow bottle): dari 76,989 psi “WENT UP A WHOPPING 30%” jadi 100,252 psi dengan “1.5 OZ of Oil Extreme concentrate”.

5W30 Pennzoil, API SN conventional (yellow bottle): dari 76,989 psi “WENT UP 29%” jadi 99,529 psi dengan “2.0 OZ of Oil Extreme concentrate”.

5W30 Pennzoil, API SN conventional (yellow bottle): dari 76,989 psi “WENT UP 27%” jadi 97,651 psi dengan “3.0 OZ of Oil Extreme concentrate”.

5W30 Pennzoil, API SN conventional (yellow bottle): dari 76,989 psi “WENT UP 26%” jadi 96,739 psi dengan “4.0 OZ of Oil Extreme concentrate”.10W30 Brad Penn, Penn Grade 1 semi-synthetic : dari 71,206 psi “WENT UP A BREATH TAKING 56%” jadi 111,061psi.

10W30 Lucas Hot Rod & Classic Hi-Performance Oil conventional : dari 62,538 psi “WENT UP A MIND BLOWING 69%” jadi 105,758 psi

5W30 Royal Purple XPR (extreme performance racing oil) synthetic : dari 74,860 psi “WENT UP 9%” jadi 81,723 psi.

10W30 Comp Cams Muscle Car & Street Rod Oil semi-synthetic : dari 60,413 psi “WENT UP AN IMPRESSIVE 24%” jadi 74,874 psi.5W30 Pennzoil Ultra, API SM synthetic : dari 115,612 psi “WENT DOWN 3.5%” jadi 111,570 psi.

5W30 Mobil 1, API SN synthetic : dari 105,875 psi “WENT DOWN 3.6%” jadi 102,059 psi.

5W30 Oil Extreme Motor Oil, API SM synthetic : dari 110,286 psi “WENT DOWN 11%” jadi 98,396 psi.

5W30 Chevron Supreme, API SN conventional : dari 100,011 psi “WENT DOWN 5.1%” jadi 94,864 psi.

5W30 Castrol GTX, API SN conventional : dari 95,392 psi “WENT DOWN 6%” jadi 89,659 psi

Bisa dilihat bahwa untuk oli yang sama 5W30 pennzoil, hasil bisa naik dan bisa turun. Tambah banyak aditifnya bukan tambah bagus anti ausnya tapi justru tambah jelek. Yang menarik lagi, oli dengan API SM ditambah aditif “Oil Extreme concentrate” justru daya perlindungan anti ausnya justru turun. Oli yang anti ausnya jelek memang jadi bagus bila ditambah aditif, tapi oli yang anti ausnya sudah bagus justru jadi lebih jelek perlindungan terhadap aus setelah ditambah aditif.

Penulis menduga bahwa oli yang anti ausnya meningkat setelah ditambah aditif itu karena aditif anti aus di olinya dikurangi, sebagai sebab dari implementasi API SN.

Ini sudah pernah penulis jelaskan sebelumnya:

Ini alasan mengapa oli dengan performa tinggi atau untuk long drain interval bisa tidak lulus uji API service

Oleh karena itu oli mesin generasi pertama setelah standar API diterapkan perlindungan terhadap aus menjadi payah, karena aditif anti ausnya kurang, sehingga saat ditambah aditif peningkatan menjadi saat maksimal. Namun setelah resep diperbaiki oleh pabriknya, tetap sesuai standar tapi dengan pengembangan aditif lebih modern, di generasi berikutnya oli API SN perlindungannya bisa sebagus yang API SM, sehingga setelah ditambah aditif perlindungan justru berkurang.

Kesimpulan lain yang sangat penting adalah, kalau olinya sudah bagus perlindungan anti ausnya, kalau ditambah aditif maka perlindungan anti aus justru makin jelek.

Jadi bro, bila suatu oli harus ditambah aditif dulu baru bisa ok anti ausnya, maka langkah yang terbaik adalah jangan menambah aditif, tapi ganti oli yang lebih baik. Oli itu jangan dipakai lagi. Kalau olinya sudah bagus, malah jangan ditambah aditif lagi, malah bisa berkurang kemampuannya. Faktor berikut juga sangat penting.

Aditif hanya memberikan perlindungan sementara atau cuma satu faktor saja dan bisa malah mengganggu kerja aditif lain

Harus diingat bahwa percobaan anti aus ini hanya dilakukan pada saat oli masih baru, padahal seharusnya percobaan dilakukan setelah oli dipakai juga. Bisa jadi setelah pemakaian aditif malah mengurangi perlindungan entah karena menjadi terurai lebih cepat atau mengganggu kerja aditif yang lain. Seperti dijelaskan di artikel berikut, yang juga menyebutkan pentingnya keseimbangan aditif:

Choosing the Right Hydraulic Fluid

The viscosity index (VI) improvers used to make multigrade oils can have a negative effect on the air separation properties of the oil. This is not ideal, particularly in mobile hydraulic systems which typically have a relatively small reservoir with correspondingly poor deaeration characteristics. The high shear rates and turbulent flow conditions often present in hydraulic systems destroy the molecular bonds of the VI improvers over time resulting in loss of viscosity. When selecting a high VI or multigrade fluid, it is recommended that the hydraulic component manufacturers’ minimum permissible viscosity values be increased by 30 percent to compensate for VI improver sheardown. This adjustment reduces the maximum permissible operating temperature that would otherwise be allowable with the selected oil and thereby provides a margin of safety for viscosity loss through VI improver shearing.

Detergent oils have the ability to emulsify water, and disperse and suspend other contaminants such as varnish and sludge. This keeps components free from deposits, however, it also means that contaminants do not settle out – they must be filtered out. These can be desirable properties in mobile hydraulic systems, which unlike industrial systems, have little opportunity for the settling and precipitation of contaminants at the reservoir, due to its relatively small volume.

The main concern with these fluids is that they have excellent water emulsifying ability, which means that if present, water is not separated out of the fluid. Water accelerates the aging of the oil, reduces lubricity and filterability, reduces seal life and leads to corrosion and cavitation. Emulsified water can be turned into steam at highly loaded parts of the system. These problems can be avoided by maintaining water content below the oil’s saturation point at operating temperature.

The purpose of antiwear additives is to maintain lubrication under boundary conditions. The most common antiwear additive used in engine and hydraulic oil is zinc dialkyl dithiophosphate (ZDDP). The presence of ZDDP is not always seen as a positive, due to the fact that it can chemically break down and attack some metals, and reduce filterability. Stabilized ZDDP chemistry has largely overcome these shortcomings, making it an essential additive to the fluid used in any high-pressure, high-performance hydraulic system, such as those fitted with piston pumps and motors. A ZDDP concentration of at least 900 parts per million can be beneficial in mobile applications.

Frequently Asked Questions about Motor Oils

Motorcycle oils have higher levels of phosphorus/zinc for enhanced wear protection and the same high-temperature detergent technology for superior wear protection and engine cleanliness, even at elevated oil temperatures. Specifically motorcycle oils for aircooled engines are designed for very high localized oil temperatures and high overall oil temperatures, and typically have high flash points coupled with higher HTHS viscosities and lower noack% losses. As a whole, it would appear that all most motorcycle oils we tested have excellent anti-wear additive levels and most are not SM or SN rated oils, but rather earlier SG, SH, or SJ rated. In a pinch, it should be fairly easy to find a motorcycle oil with any of these SG, SH, or SJ ratings at your local auto parts store when it may be more difficult to get Brad Penn or Swepco, without having it shipped to you. Please do remember that motorcycle oils typically have levels of Zn and P that will kill catalytic converters, so if you have one, either remove it first or use another oil, like Brad Penn or Swepco. Also, motorcycle oils are not as detergent as the aforementioned Brad Penn or Swepco, so you must change the oil much more often, even though the perception of being able to go longer because the oil costs more is a false one.

Beware of ZDDP boosters and concentrates being sold under various names. These products should truly only be used at time of break-in or not at all if a fully-formulated break-in oil is used.

Products previously sold to boost ZDDP, like STP or GM EOS, always had roughly an equal amount of detergents to offset the affect of ZDDP in reducing the TBN of motor oil. Most of these ZDDP concentrates omit detergents altogether or use over-based Ca detergents known to reduce the efficiency of the anti-wear properties of the oil! Just like you need more Zn and P in an oil that has more detergents, you also have to have additional detergency because of the breakdown of ZDDP in peroxides and its interaction with combustion byproducts to form sulfuric acid. Knowing the right balance is something best left to the oil manufacturers and their chemical engineers. More acid, will increase the oils TAN, and will lead to corrosive wear of bearings. For once, I will have to say that more is not better, especially in this case. EOS and STP are decades old, and proven products that work synergistically with your existing motor oil and were never designed to boost the Zn and P more than 100-200ppm – unlike some recommendations to run double the ZDDP, in excess of 2000 ppm, which can lead to increased wear! It is not only the level of Zn and P that is important, but also starting with an oil that meets the ACEA A3/B3 standard would assure a starting TBN of 10 or higher and with similarly higher HTHS viscosities will also give you greater protection too. If you do choose to use these products, you must do used oil analysis to determine drain intervals and monitor overall TBN retention and ensure that the TAN increase does not lead to increased bearing wear! Too much ZDDP can also foul spark plugs and oxygen sensors, not to mention plug EGR valves and the catalytic converter. Additionally, lack of testing of these ZDDP boosters compared to fully formulated oils intended for racing or for older engines or even against SM or SN-rated oils side by side do not instill confidence in their performance, or at least at the time this was written.

Aditif VI improver dipergunakan di oli multigrade untuk membuat oli jadi tidak terlalu cair saat panas. Namun efek dari aditif ini akan bisa berkurang karena shear dan turbulent flow. Oleh karena itu kekentalan perlu ditingkatkan 30% dari kebutuhan untuk mencegah berkurangnya perlindungan karena berkurangnya kekentalan karena terurainya VI improver.

Aditif detergent punya kemampuan untuk membuat air bisa bercampur dengan oli, memecah dan melarutkan particle pencemar lain semacam kerak dan lumpur. Ini membuat mesin bersih dari kotoran. Ini artinya kotoran tidak mengendap dan harus disaring. Masalah terjadi karena ini menyebabkan air tercampur dengan oli, sementara itu air memperpendek umur oli, mengurangi daya pelumasan, mengurangi kemampuan untuk di filtrasi, mengurangi umur seal, dan mempercepat korosi dan membuat rongga rongga.

Aditif anti aus ZDDP membantu meningkatkan daya perlindungan oli. Namun kelemahannya bisa terurai dan akan merusak beberapa tipe logam dan mengurangi kemampuan untuk di filtrasi.

Zinc Versus Detergent In Motor Oil

The oil additive Zinc DialkylDithioPhosphate (ZDDP) works because it is a polar molecule, so it is attracted to ferrous metal surfaces. However, Zinc (ZDDP) is not a lubricant until heat and load are applied. ZDDP must react with heat and load to create the sacrificial film that allows ZDDP to protect flat-tappet camshafts and other highly loaded engine parts. Not all ZDDP additives are the same. Some zinc additives have slower “burn” rates that require more heat and more load to activate than other zinc additives. As a result, not all “High Zinc” oils have the same activation rate. The Driven BR Break-In oil uses a “Fast Burn” ZDDP that activates quickly.

Detergents and dispersants in the oil complicate the situation. Detergent and dispersant additives “compete” against zinc in the engine because they are polar molecules as well. Detergents and dispersants clean the engine, but they don’t distinguish between sludge, varnish and zinc – they clean all three away. Modern API certified oils contain higher levels of detergents and dispersants due to the exhaust gas recirculation (EGR) systems on passenger cars and diesel trucks. The “old school” theory on engine break-in was to run non-detergent oils, and this allowed for greater activation of the zinc additive in the oil.

Aditif ZDDP melindungi mesin karena zat itu bersifat polar, yang akan menempel pada permukaan logam yang bersifat ferromagnetic. ZDDP baru akan melindungi mesin setelah ada panas dan tekanan. Tidak semua aditif ZDDP sama, ada yang cepat bereaksi melindungi ada yang lambat. Untuk break in diperlukan aditif ZDDP yang cepat bereaksi.

Aditif detergent dan dispersant bisa mengganggu kerja aditif ZDDP karena mereka bersidat polar juga. Detergent dan dispersant akan membersihkan mesin namun tidak membedakan antara yang harus dibersihkan seperti kerak, lumpur dan air dengan aditif ZDDP. Jadi aditif ZDDP akan juga ikut dibersihkan. Aditif untuk break in membutuhkan lebih sedikit detergent untuk membuat aditif zinc bisa lebih aktif.

Sepertinya ini pula yang membuat oli racing dibuat dengan lebih sedikit aditif, sehingga tidak cocok untuk harian. Oli racing atau oli untuk balap seringkali dibuat dengan fokus pada perlindungan anti aus yang bila perlu akan mengorbankan faktor pembersihan.

Racing Oil vs. Street Oil: Know the Differences

Some street performance oils balance higher ZDDP levels with less detergent, but you can still race and change every 3,000 miles. Others do not sacrifice detergency and oil cleanliness, and still maintain exceptional wear protection for extended drain intervals. The oil manufacturer’s tech line should be called to determine the useful life of their products.

Jadi dengan menambahkan aditif ke oli mesin, maka keseimbangan aditif menjadi terganggu. Misalkan aditif itu untuk menambahkan sifat anti aus, maka daya pembersihan mesin bisa berkurang, dan bila aditifnya berlebihan, bisa mengganggu filtrasi oli yang akhirnya bisa menimbulkan masalah.

Kebutuhan aditif anti aus sangat tergantung pada keperluan

The Truth About Zinc & Motor Oil

Are you ready for some good news? The key to how much and what type of Zinc your engine needs depends on your engine’s valve train. If you have a stock valve train and no other performance modifications, then an API licensed oil is all you need. Every API licensed oil will protect stock engines under normal street driving cycles. When you start making performance modifications or begin racing, everything changes. Higher lift cams with longer durations and greater spring pressures need a faster response from the Zinc. Basically, the Zinc package needs to be optimized for the application, and this is where the confusion happens.

Many people have had good success with premium API licensed products in stock engine applications (as well they should). When you go beyond normal valve lift, operating temperatures and cylinder pressures, the oil formula needs to adapt to these “new” requirements. Because the modifications fall outside the OEM guidelines used by the API to determine oil performance specifications, an API performance level does not apply.

detergents and dispersant additives in motor oil actually compete against the Zinc in your engine. That’s right. Zinc is not alone in your motor oil. Several other additives like detergents, dispersants, viscosity index improvers, and others all compete against the Zinc inside your engine – sometimes with negative consequences.

Back in August of 2005 (less than a year after API SM was introduced), the Society of Tribologists and Lubrication Engineers published a story stating that calcium-based detergents and dispersants competed against the ZDDP for surface space, and that caused some wear issues in passenger car engines. Around this same time many engine builders began to experience a rash of flat tappet cam failures during break-in.

The level of ZDDP had also been reduced in the API SM oil spec, and along with the increased use of calcium detergents and dispersants, the critical balance had shifted. The results were nearly catastrophic for independent engine builders and camshaft manufacturers. The rate of flat tappet cam failures escalated at an alarming rate.

The decrease in ZDDP from 1,000 ppm down to 800 ppm was called out as the cause for the rash of cam failures. This failed to take into account the change in ZDDP to detergent balance. Many engine builders switched to diesel oils that contained higher levels of ZDDP, and that worked sufficiently until the diesel oils underwent a reduction in ZDDP down to 1,200 ppm in October of 2006. By the end of 2007, engine builders were again on hunt for a higher Zinc solution. This time, many switched to properly formulated break-in oils high in ZDDP and low in detergent. Some still held onto the diesel oils, but also added an off-the-shelf ZDDP supplement.

A perfect example of proper balance can be seen is an API SN motor oil. While this spec oil is limited to 800 ppm of a catalytic converter friendly ZDDP, an API SN oil can break in a flat tappet camshaft. The flat tappet cam in question has less than .400 valve lift and no more than 215 psi valve spring pressure. So an API SN oil will protect a flat tappet cam, but you won’t see success trying to break in a Big Block Chevy cam with over .500 valve lift and over 300 psi valve spring pressure with an API SN oil. It is the different demands of the valve train loads that dictate what balance is required to protect.

The bottom line is that bigger lift, longer duration cams with more spring pressure need a proper break-in oil to establish that critical anti-wear film. After break-in, a hot rod-style oil for street/strip should be used to maintain that protective Zinc film. Race applications meanwhile need a proper racing oil to deliver race-specific performance.

A stock V8 may look very similar to a hot rod V8 or a racing V8, but in reality each of these applications needs a different balance to provide the proper protection for the investment. The good news is that specialty oils are now available that provide the application- specific protection performance engines need, letting you choose the correct oil for your engine every time.

Dikatakan bila mesin dalam keadaan standar, maka oli dengan sertifikasi API akan sudah mencukupi untuk keperluan sehari hari. Namun bila mesin sudah dimodifikasi ekstrem (hp sangat besar) dan dipakai balapan (kencang berjam jam) maka oli standar sudah tidak lagi memadai.

Aditif zinc yang biasa dipakai untuk perlindungan mesin sering konflik dengan aditif untuk pembersih, pelarut, dan viscosity index improver, yang bisa menimbulkan efek buruk. Jumlah yang tidak seimbang bisa menimbulkan kerusakan.

Beberapa waktu setelah API SM diperkenalkan, banyak yang mengalami masalah keausan di kendaraan karena ternyata berkurangnya aditif ZDDP tidak disertai dengan dikuranginya aditif yang lain, sehingga aditif ZDDP tidak bisa bekerja dengan baik dan membuat mesin jadi lebih cepat aus. Namun setelah resep diperbaiki masalah tidak terjadi lagi.

Sifat anti aus ditingkatkan dengan menambahkan zat lain yang punya fungsi sama walau akhirnya jadi bikin harga lebih mahal.

GF-6, PC-11 and dexos1™: New engine oil specifications mean new additive challenges, Dr. Neil Canter

As explained by Fricke, universal oils that can operate in both gasoline and diesel engines will need to operate at a lower phosphorus limit (800 ppm as compared to 1200 ppm) to meet the GF-6 specification. He says, “Universal oils are low total base number, low phosphorus engine oils that are specially engineered to comply with gasoline aftertreatment systems and not poison the catalysts.

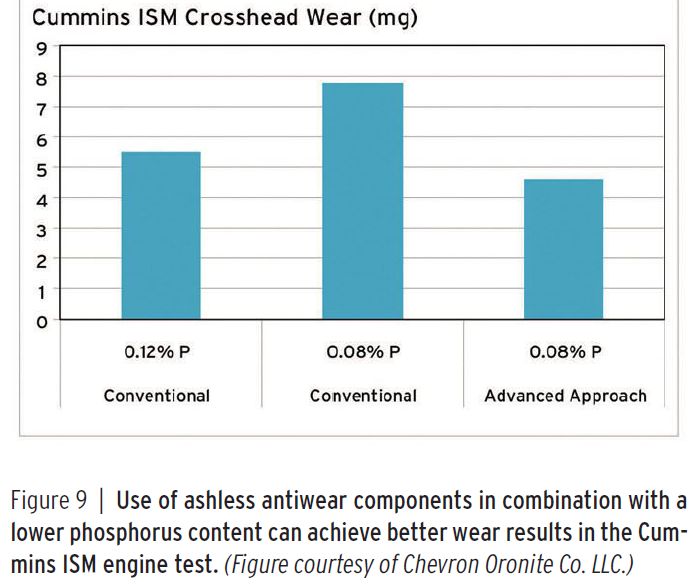

Phosphorus reduction means that the best method to evaluate the efficacy of universal oils is through wear testing. The Cummins ISM engine test that measures engine wear and deposits under heavy-duty operating conditions is the desired technique to use. Shaw presents data from that test (see Figure 9 on page 22) showing the results of an advanced approach. He says, “Use of ashless antiwear components in a balanced formulation affords better results than what are seen with conventional formulations. All other performance attributes also are met with this new formulation.”

Haffner makes the case that formulation costs will increase in trying to develop a universal oil. He says, “In general, it is more costly to formulate at a lower phosphorus level. ZDDPs are one of the most cost effective antiwear/antioxidant additives available and low ZDDP formulations need to be supplemented with alternative additives. One of the real issues with low phosphorus HDEO formulations is the level of comfort of OEMs and end-users due to the lesser amount of field experience that exists, in particular in older engines.”

Bisa juga dilihat di grafik berikut, dimana walau kandungan ZDDP dikurangi, hasil perlindungannya bisa sama dengan sebelum dikurangi bila ditambahkan aditif yang lain.

Walau oli dengan standar API SN sudah cukup untuk melindungi mesin standar dengan tenaga besar, oli tidak cukup melindungi bila mesin tersebut dimodifikasi ekstrem.

Disarankan untuk memilih oli sesuai dengan keperluan. Pabrikan oli juga sudah menyediakan banyak pilihan sesuai dengan keperluan pemakaian.

Ini juga yang menjadi alasan mengapa oli untuk balap menjadi tidak cocok untuk harian. Karena oli untuk balap fokusnya lebih ke perlindungan dan tidak begitu mempertimbangkan kebersihan mesin untuk pemakaian jangka panjang.

Kesimpulan

Oli yang sudah bagus perlindungannya justru jadi berkurang perlindungannya bila ditambah

Daripada pakai oli ditambah aditif, mending sekalian pilih oli yang perlindungannya bagus

Menambah aditif justru bisa mengganggu keseimbangan kimia di oli dan membuat oli umurnya jadi jauh lebih pendek, bisa justru merusak mesin, dan berkurang daya perlindungan atau daya pembersihannya.

Oowww

Pengetahuan baru nih

SukaSuka

Ane pake nano,,, pas overhaul kemaren (service besar), kebetulan mesti ganti ring piston,,, ane perhatikan ada kerak di oil ring nya,,, jadi partikel keramik nya nempel dan jadi kera di ring oli.

SukaSuka

Ok. ring bagian ruang oli atau bagian ruang bakar?

SukaSuka

ring oli cuma satu,,, dikedua sisi nya ada kerak agak putih kehitaman,,,

SukaSuka

sip, makasih infonya

SukaSuka

[…] Kalau untuk pakai aditif tambah sendiri, sebaiknya tanya dari yang sudah pakai, karena kalau tidak pas bisa malah tidak baik efeknya: Pakai aditif oli mesin bisa justru malah mengurangi daya perlindungan ke mesin, alasan untuk menghin… […]

SukaSuka

[…] Kualitas oli tidak hanya ditentukan dari base oilnya saja tapi juga dari aditif. Aditif juga tidak hanya bisa dilihat dari satu unsur saja, karena bisa jadi dengan misalkan kada ZDDP sama secara keseluruhan perlindungannya berbeda. Ini sudah pernah penulis bahas disini: Pakai aditif oli mesin bisa justru malah mengurangi daya perlindungan ke mesin, alasan untuk menghin… […]

SukaSuka

[…] Penggunaan aditif tidak bisa langsung dimaksimalkan semuanya, tidak bisa asal menaikkan konsentrasi, karena suatu aditif bisa juga mengganggu kerja dari aditif lain. Seperti contohnya aditif pembersih dan pelarut dengan aditif pelindung zinc. Keduanya bisa mengganggu kerja satu sama lain, contoh referensinya: Zinc Versus Detergent In Motor Oil […]

SukaSuka

[…] Bila minyak goreng dipergunakan tanpa aditif dan oli tidak diganti pada waktunya maka sebagai akibatnya mesin bisa menjadi berkerak atau terjadi sludge.

Tidak cuma minyak goreng yang mengalami ini, namun bahkan oli sekelas Amsoil pun bisa mengalami. Sebaik apapun olinya, kalau masa pemakaian terlalu lama atau oli mesinnya kurang maka tetap akan mengalami resiko sludge (lumpur mesin) atau varnish (kerak mesin). […]

SukaSuka

[…] Pakai aditif oli mesin bisa justru malah mengurangi daya perlindungan ke mesin, alasan untuk menghin… […]

SukaSuka

[…] Pakai aditif oli mesin bisa justru malah mengurangi daya perlindungan ke mesin, alasan untuk menghin… […]

SukaSuka