Pada waktu penulis memuat daftar hasil karya mbak Deesanti, penulis kaget juga saat menemukan bahwa banyak sekali oli yang disebut sintetik tapi bahannya pakai VHVI atau grup III+. Dari banyak postingan juga banyak disebutkan bahwa ada beberapa jenis oli yang menganti ramuan basestock oil dari yang asalnya pakai PAO menjadi pakai VHVI.

Dari sisi kemampuan, oli dari bahan dasar PAO kemampuannya kalah dari oli VHVI, namun mengapa sekarang banyak pabrikan oli yang beralih dari PAO ke VHVI?

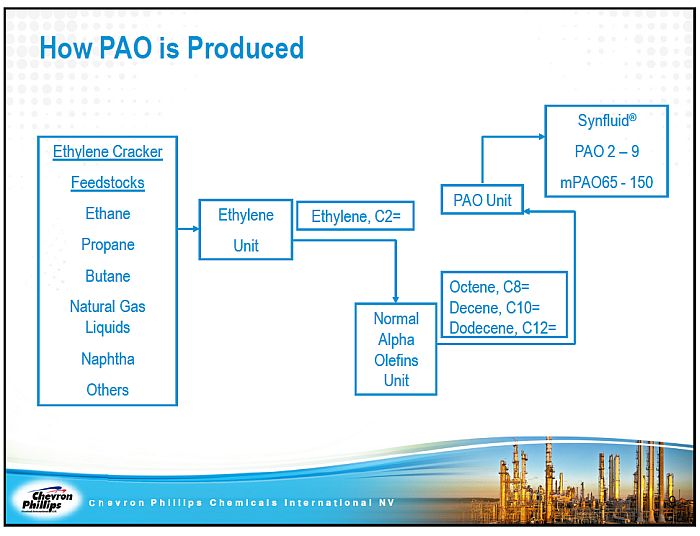

Secara pembuatan, oli PAO dikatakan lebih susah dibuat:

Penggunaan Oli Mobil (PCMO/HDEO) untuk Motor, Composed and Edited by Dee santi

PAO ini dikenal sebagai Base Stock ngambekan, alasannya adalah selain pembuatannya sulit, yaitu apabila oli dengan PAO Based akan dibuat maka bahan-bahan seperti additives pack harus dicampur sebelum menjadi oli. PAO sangat sulit ditambahkan soluble additives, sehingga additives yang bisa ditambah biasanya adalah logam alkali, alkali tanah, atau logam transisi seperti Molybdenum dan Titanium. Logam alkali ditambahkan adalah supaya menambah retensi pelumas untuk menahan asam yang terbentuk saat pembakaran terjadi. PAO juga sangat rewel apabila bertemu dengan racun sejenis Sulfur dan TEL atau Tetra-Ethyl-Lead, dan dia tidak bisa ditambah dengan post-mixed additives.

New base oils pose a challenge for solubility and lubricity

Low solubility not only makes it difficult to dissolve some essential additives, but it also compromises some essential quality parameters, such as dispersancy and seal compatibility. For instance, PAOs are unbeatable in terms of pour point and volatility, and at the same time, have the lowest lubricity and solubility ranking. This is normally compensated by using solubility improvers in finished lubricant formulations.

As base oils are concerned, solvent power is chiefly determined by polarity of oil molecules. PAOs are non-polar, so they have low solvent power. Esters are polar, so they have high solvent power.

(i) Blend with naphthenic basestocks or alkylaromates. Improvement in solvency comes at a price of a loss in viscosity index. Naphthenics have no effect on lubricity.

(ii) Retro-blend with Group I basestocks. Improvements in solvency and lubricity come at a price of deteriorating viscosity index, Noack volatility, pour point, antioxidant response, and health safety and environmental (HSE) profile.

(iii) Blend with synthetic esters. Improvement in solvency comes at a price of downgrading high-temperature stability. Saturated branched-chain fatty esters themselves often lack lubricity. Even more dangerous is that some linear-chain esters passivate the surface against reaction with extreme pressure (EP) additives, undermining anti-wear protection at high loads.

(iv) Blend with vegetable oils. This technology existed before synthetic esters. Vegetable oils have their own advantages and disadvantages. The chief advantages are the use of a renewable resource, excellent lubricity and anti-wear properties, excellent thermal stability, high specific heat, high flash, and completely benign HSE profile. The chief disadvantage is low oxidation stability.

(v) Blend with ionised vegetable oils. These products have rather unique properties, inheriting their positive features such as high lubricity and anti-wear efficiency from vegetable oil, and at the same time adding oxidation stability and anti-sludge capability.

Secara penamaan, oli dari bahan VHVI juga dikategorikan oli sintetik, tidak hanya PAO saja:

Ada perbedaan antara pasaran dunia dan Eropa, pasaran dunia Oli Group III+ dapat disebut sebagai Fully-Synthetic, sementara di Eropa Oli Group III+ hanya boleh disebut Synthetic Technology. Untuk membedakannya, bisa dibuka http://www.total.fr/ dimana oli yang dijual sebagian besar di luar Eropa disebut sebagai Fully-Synthetic, maka di Perancis hanya disebut Lubrifiant technologie de synthèse atau Synthetic Technology Lubricant. Di Eropa hanya Group IV dan Group V yang boleh di label dengan Fully-Synthetic Lubricant.

Oli PAO pun dibilang makin langka karena permintaan lebih banyak dari produksi:

PAO – meeting the challenge of increased demand

One of the key challenges in the PAO industry is how to meet increased demand with limited decene feedstock availability.

“To maintain raw material availability, companies have had to look at alternate sources of material that provide additional flexibility in their manufacturing process.”

Skip Thomas, Global Market Segment Manager, Synthetics, ExxonMobil Chemical Company“Today, we use a mixed alpha olefin feed platform for production of the majority of our PAOs,” Skip Thomas continues. “This allows the extension of PAO supply to our customers in a limited LAO feed supply environment, like today. With our proprietary technology and extensive product testing, we are able to produce mixed alpha-olefin PAOs that perform equivalently and interchangeably with decene-based PAOs.”

Dikatakan bahwa kesulitan pembuatan PAO adalah karena kesulitan untuk bahan decene, sehingga harus diakali pakai mixed alpha olefin.

Jadi oli PAO sulit dibuat, makin langka dan sekalipun pakai VHVI oli tetap bisa dibilang oli sintetik.

Apakah alasan ini saja sudah cukup? Kebetulan bro Selamat memberikan clue untuk membuat artikel tentang proses dari shell untuk membuat oli dengan nama gas to liquid (GTL). Menurut penulis ini sepertinya bisa jadi alasan kuat mengapa pabrikan mulai menggunakan basestock oli yang dihasilkan dari proses GTL.

Berikut penjelasan menurut Shell:

What is gas-to-liquids?

Shell’s gas-to-liquids (GTL) technology converts natural gas – the cleanest-burning fossil fuel – into high-quality liquid products that would otherwise be made from crude oil. These products include transportation fuels, motor oils and the ingredients for everyday necessities like plastics, detergents and cosmetics.

GTL products are colourless and odourless. They contain almost none of the impurities – sulphur, aromatics and nitrogen – that are found in crude oil.

Dikatakan bahwa teknologi Shell gas to liquid (GTL, gas jadi cairan) merubah gas alam (biasa jadi LNG) – bahan bakar fosil yang paling bersih – menjadi produk cairan kualitas tinggi yang biasanya dibuat dari minyak mentah. Produk ini bisa berupa bahan bakar transportasi, oli mesin atau bahan untuk kebutuhan sehari hari seperti plastik, deterjen atau kosmetika.

Produk dari GTL ini tidak berwarna dan tidak berbau. Produk tidak mengandung zat ketidakmurnian seperti sulfur, aromatik dan nitrogen yang biasa ada pada minyak mentah.

Oleh shell, oli yang dibuat dari proses GTL dinamakan oli pureplus:

Oli GTL itu dibuat dengan cara yang sama dengan oli sintetik, yaitu dengan proses

Namun dikategorikan sebagai oli grup III

GTL innovation produces clean base oils from natural gas

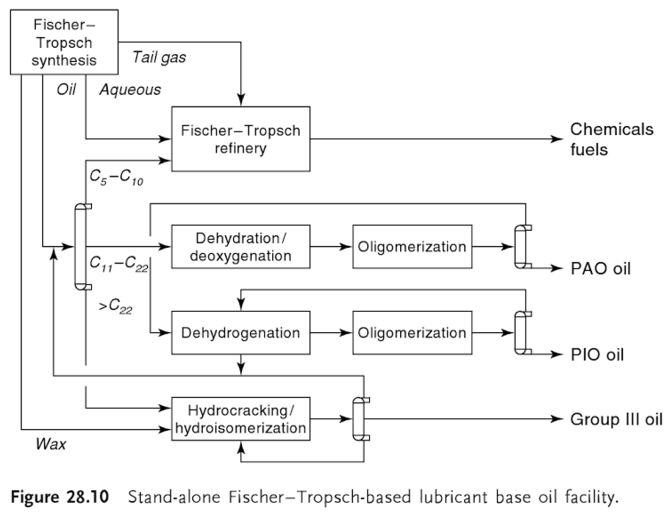

Shell GTL base oils are classified as Group III base oils. The heart of Shell’s GTL technology is Fischer-Tropsch (FT) synthesis, based on the catalytic production of paraffin hydrocarbons from carbon monoxide (CO) and hydrogen (H2).2 Natural gas, the cleanest-burning fossil fuel, was chosen as the preferred hydrocarbon source because it is affordable, available and environmentally acceptable.

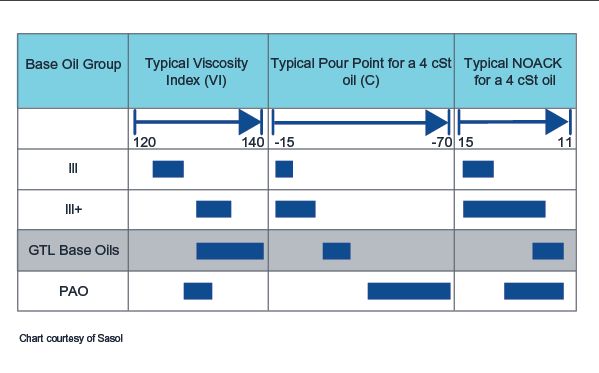

Dari sisi kemurnian, GTL jadi mendekati PAO.

Di faktor lain juga kemampuan oli GTL mendekati PAO.

Gas to Liquids – Conversions Produce Extremely Pure Base Oils

The lubricant base stock created in the gas to oil conversion is called an ISO paraffin. The Viscosity Index (VI) of iso-paraffins is extremely high while providing excellent oxidation resistance and good pour points.

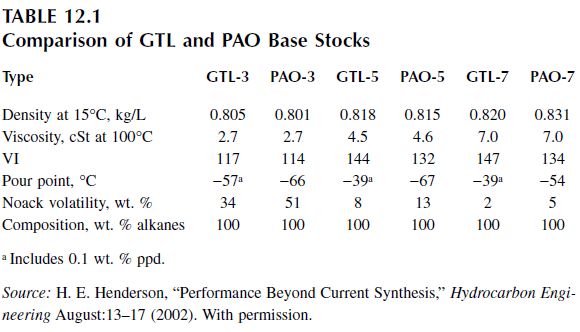

“GTL provides the best combination of kinematic viscosity VI, pour point, volatility and composition when compared with commercially available API Group III base stocks,” Henderson said. He further noted that in most cases, the properties of GTL fluids exceed the industry range for any base stock properties, as seen in Table 1.

“GTL fluids also provide an excellent match for PAOs,” Henderson said. “Their excellent VI, flash point and volatility more than offset the marginal low temperature property represented by pour point which can be further improved if necessary through increased dewaxing severity.”

“The Sequence IIIF test results included exceptional oil consumption for the GTL formulation as a SAE 0W-20 viscosity grade, excellent viscosity increase control, oil consumption comparable to API Group III/IV oils of higher SAE viscosity grades, and excellent deposit results.

“They have an outstanding combination of viscometric, volatility, low-temperature and compositional properties that exceed the American Petroleum Institute’s Group III ‘Best of Industry’ while matching PAO standards.”

Dikatakan bahwa bahan pelumas yang dibuat dengan proses GTL disebut dengan nama ISO paraffin. VI iso paraffin sangat tinggi walau juga mempunyai daya tahan oksidasi yang bagus sekali dan titik tuang yang bagus.

GTL mempunyai VI, pour point, volatility dan komposisi yang lebih baik dari API grup III. Sifatnya melebihi dari kebutuhan industri oli. Oli GTL cocok untuk menggantikan PAO.

Pada pengujian sequence IIIF menunjukkan formula oli GTL SAE 0W-20 punya oil consumption yang sangat baik, kontrol kenaikan kekentalan sangat baik. Dengan konsumsi oli setara dengan oli grup III/IV dengan SAE grade lebih tinggi dan kontrol kerak yang sangat baik.

Oli GTL punya sifat yang melebihi sifat dari oli terbaik grup III dari proses normal, dan menyamai standar oli PAO.

Bahkan untuk NOACK volatility angka bisa lebih baik dari PAO:

Process Chemistry of lubricants base stocks

Proses dan sifat dari oli GTL dikatakan juga ramah lingkungan:

Gas to Liquids – Conversions Produce Extremely Pure Base Oils

Eliminating Costly and/or Environmentally Disadvantageous Practices

GTL will help eliminate the need for flaring natural gas associated with oil production. This will permit earlier development and production of oil fields shut in by the inability to dispose of the associated natural gas, and reduce the negative environmental impact of flaring.Creating Environmentally Superior Liquid Fuels

GTL will yield synthetic hydrocarbons of the highest quality that can be used directly as fuels or blended with lower-quality crude oil derived fuels to bring them up to compliance with increasingly stringent environmental and performance specifications.

Ada satu lagi yang membuat oli GTL sangat unggul, harga produksinya:

A US MARKET SPACE ANALYSIS OF GTL LUBRICANTS, Copyright © Petroleum Trends International, Inc. 2002

According to a multiclient study recently completed by Nextant Chem Systems, the manufacturing costs for GTL delivered in the US market are comparable with that of Group I, II, and II+. Even more importantly, ChemSystems’ analysis reveals that the economics for GTL are more favorable than that of high VI Group III, as shown in Figure 1

Dikatakan bahwa biaya produksi dari oli GTL setara dengan biaya pembuatan oli grup I, II dan II+. Secara ekonomis lebih menguntungkan daripada oli grup III HVI.

Bila dirangkum berdasarkan kemampuan dan harga maka grafiknya sebagai berikut:

Jadi oli GTL itu biayanya murah dengan kemampuan lebih baik dari oli VHVI dari proses normal, dimasukkan ke oli kategori III dan mendekati kemampuan oli PAO. Sementara oli PAO sendiri selain biaya pembuatan mahal, bahannya langka, dan juga bagi konsumen namanya sama sama oli sintetik. Ini tentu menggiurkan bagi pabrik oli.

Surging GTL promises lube-market opportunities

Lube oils produced through the Fischer Tropsch process show the following attributes (Table 4):1 7 8

• Viscosity index ranging from 140 to 155 as compared with Group IV-PAO that have a VI in the range of 120-140 for the same viscosity grades.

• NOACK volatilities (ASTM D-5800) below 10 wt %, that is significantly lower than Group II/II+ and III base oils.

• Pour point of GTL base oils is, however, much closer to that of a Group III. This can be addressed by the use of pour point depressant additives. Advantageously, GTL base oils are reported to have excellent responsiveness to methacrylate-based pour point depressants.

• GTL base oils have no detectable levels of sulfur, nitrogen, or aromatics compounds. They have very narrow hydrocarbon distribution and have excellent oxidation stability and biodegradability characteristics.

In addition to high quality, GTL base oils also have very favorable manufacturing economics. Some studies indicated that the manufacturing costs for GTL delivered in the mature markets are comparable with that of Group I, II, and II+.1 7 Even more importantly, the economics for GTL are more favorable than that of high-VI Group III.

GTL base oil competes with Group III and Group IV-PAO in automotive lubricants markets. The performance advantages of GTL base oil over Group III will likely be found in several key aspects:7 8

• Superiority of its lower volatility over that of Group III.

• Low formulation cost to capture market share from Group III and Group IV-PAO.

• GTL base oil provides environmentally friendly solutions to the industrial lubricants market due to its biodegradability and its absence of sulfur, nitrogen, and aromatics compounds.

Dimasa depan pabrik oli pada ramai ramai membuat kilang GTL juga:

Gas-to-liquids: much smoke, little fire

Second-generation. Notwithstanding the poor results of these first-generation GTL facilities, the pioneers (i.e., Mobil, Sasol and Shell) went back to their drawing boards and came up with second-generation GTL processes. Other companies such as Exxon, BP, Syntroleum, Conoco and Rentech2 joined the fray and developed their own GTL technology. Thus, with the three “supermajor” oil companies (BP, Exxon and Shell) onboard, the GTL train picked up steam.

Pabrik oli pada beramai ramai migrasi dari PAO ke GTL juga:

PAO on the radar

Infineum sees additional uncertainty as some lubricant marketers adjust their formulations in response to PAO availability. “PAO is definitely high on our customers’ radar screens,” says Infineum’s Yannick Jullien. “We are finding that some formulations are being modified to reduce PAO content – something that is an irreversible change. What’s more,” he continues, “as GTL, or other Group III plus, kicks into OEM factory fill oils, PAO demand is likely to be further reduced, although it is too difficult to predict accurately the impact on each PAO grade.”

Yang jadi penghalang mungkin biaya investasi:

Kline Analysts: Qatar/Exxonmobil’s Cancelled GTL Plans Open Doors for Group III Basestock Refiners

“We think ExxonMobil will be short on Group III by 2015 and will either need to buy basestocks on the open market or add grassroots capacity to convert fuel hydrocracker bottoms for their own internal needs,” Agashe says. “This would require a much smaller total investment––around $250 to $300 million for the basestock refining investment––as opposed to $18 billion-plus for an entire GTL facility. Either way, formulators looking to ExxonMobil’s GTL basestocks to meet their high-performance basestock needs might have to look for other avenues.”

Nah, efek untuk konsumen bagaimana? Berikut ada contoh dimana ada oli Mobil 1 FS yang asalnya PAO jadi juga pakai bahan GTL:

New Formulation Mobil 1 FS 0W-40 Oil Does NOT Meet GT-R Specifications

Mobil 1 has reformulated their 0W-40 into 2 separate products (FS and ESP), with the Mobil 1 FS 0W-40 being the one to be used in our GT-R’s. On the rear label of the jug, the new formulation is no longer stated to “Meet or exceed the requirements of… Nissan GT-R”, along with BMW & Chrysler being removed. You can spot the new formulation easily, as it no longer states approved for BMW on the front label in yellow large font letters, simply stating “Approved for most Mercedes-Benz, VW, Audi & Porsche”, along with small white FS letters to the bottom, far right, of the Mobil 1 logo, by the lower portion of handle. They have also drastically decreased their own recommended applications from 7 to 1, simply stating “Is recommended by ExxonMobil for use in applications requiring VW 503 01.”, dropping SAAB, 3 FIAT’s and 2 OPEL’s.

It was stated in a Bob the Oil Guy forum when comparing the data sheets from the old and new formulations, that this new formulation is about 5-7% thinner and is barely a 40 weight, and will drop to a 30 weight as usage occurs (due to shearing, etc). The BTOG thread (page 4) also stated that the new formulation “Mobil 1 FS 0w-40 that is GTL based is actually VERY similar in viscosity to the original Mobil 1 0w-40 that was PAO-based” [original 0W-40= prior to R35??] and page 1 stating the new FS formulation is “10-20% PAO and 40-70% GTL” The new formulation is supposed to be better in cold weather applications. Some have speculated FS will provide less wear protection.

In the meantime, until this is clarified, those that choose to purchase/stock up on the old formulation prior to their next oil change, there’s a $12/5qt rebate from Mobil 1 ($15 rebate with filter) until May 31st, limit 2. After rebate, it comes out to $13.47/5qt jug at Wal-Mart

New Formula:

Approvals:

– API SN, ACEA A3/B3, A3/B4

– MB 229.3, 229.5, VW 502 00/505 00, Porsche A40

Specs:

@ 40ºC ……………………………………………………………..70.8

@ 100ºC…………………………………………………………….12.9

Viscosity Index……………………………………………………..186

MRV at -40ºC, cP (ASTM D4684) …………………………………..21600

HTHS Viscosity, mPa•s @ 150ºC, (ASTM D4683)…………………..3.6

Total Base Number (ASTM D2896)…………………………………12.6

Sulfated Ash, wt% (ASTM D874)……………………………………1.34

Phosphorous, wt% (ASTM D4981)…………………………………..0.1

Flash Point, ºC (ASTM D92)………………………………………..226

Density @15ºC, g/ml (ASTM D4052)……………………………….0.8456Old Formula

Approvals:

– API SN, ACEA A3/B3, A3/B4

– MB 229.3, 229.5, LL-01, VW 502 00/505 00, Porsche A40, Nissan GT-RSpecs:

@ 40ºC ……………………………………………………………..75

@ 100ºC…………………………………………………………….13.5

Viscosity Index……………………………………………………..185

MRV at -40ºC, cP (ASTM D4684) …………………………………..31000

HTHS Viscosity, mPa•s @ 150ºC, (ASTM D4683)…………………..3.8

Total Base Number (ASTM D2896)…………………………………11.8

Sulfated Ash, wt% (ASTM D874)……………………………………1.3

Phosphorous, wt% (ASTM D4981)…………………………………..0.1

Flash Point, ºC (ASTM D92)………………………………………..230

Density @15ºC, g/ml (ASTM D4052)……………………………….0.85

From the MSDS for the new Mobil 1 FS 0w-40:

1-DECENE, HOMOPOLYMER HYDROGENATED 68037-01-4 10 – < 20% H304

DISTILLATES (FISCHER – TROPSCH), HEAVY, C18-50 – BRANCHED, CYCLIC AND LINEAR 848301-69-9 40 – < 70% H304So it is 10-20% PAO and 40-70% GTL!!!

Link tersebut mengungkapkan kekhawatiran terhadap perubahan komposisi dari oli Mobil 1 FS 0W-40, dimana formula oli yang baru sertifikasinya berkurang. Dikatakan sifat oli berubah dan di versi baru terdeteksi juga kandungan GTL. Di link tersebut juga mengikutkan perbedaan spesifikasi di datasheet dan hasil oil analysis Blackstone.

Kasus ini membuat oli mobil 1 FS formula baru tidak lagi disarankan untuk kendaraan Nissan GT-R, dan disarankan untuk pakai untuk cari formula lama.

Update, untuk performa ada contoh dari Mobil 1 FS 0W40 saran dari bro Selamat, diwebsite 540 rat, dimana film strengthlah yang diukur. Film strength menunjukkan perlindungan seberapa mampu pelumas bisa menjaga agar lapisan oli bisa tetap melapisi permukaan komponen mesin. Additive yang berpengaruh di tahap ini adalah additive friction modifier dan film strength modifier. Bila lapisan oli sudah tidak lagi bisa menahan tekanan, maka additive anti wear yang bekerja. Bila tekanan makin kuat, maka additive Extreme protection akan mencegah welding dari kedua komponen yang bertumbukan. Ini akan penulis bahas lebih lanjut di artikel berikutnya. Sementara itu perbandingan dari Mobil 1 new dengan GTL dan Mobil 1 old dari PAO bisa dilihat sebagai berikut:

Di website 504 Rat

3. 0W40 Mobil 1 “FS” European Car Formula, API SN, synthetic = 127,221 psi

This new oil replaces the older version called, 0W40 Mobil 1, European Formula, API SN, synthetic. See below for the older version’s ranking position. This new “FS” version was tested in Summer 2016. This oil produced the highest psi value ever seen in my testing, from any motor oil just as it comes right out of the bottle, with no aftermarket additives. Very impressive.100. 0W40 Mobil 1, European Formula, API SN, made in the U.S., synthetic = 82,644 psi

This is an earlier version that has been replaced by 0W40 Mobil 1 “FS” European Car Formula. See above for the newer version’s ranking position.

Sepertinya, dengan adanya oli GTL ini maka harga oli dengan kualitas bagus bisa jadi turun. Namun dengan makin banyaknya pabrikan yang mengubah komposisi PAO dari produknya menjadi VHVI, maka akan makin menyulitkan konsumen yang bersedia menyediakan dana lebih demi untuk ingin mendapatkan produk dengan bahan dasar PAO.

Mantab sekali artikelnya! Dua jempol buat penulis.

Memang GTL ini utk kedepannya akan makin bnyk digunakan oleh para formulator oli.

Perlu dicatat, di artikel yg ditulis oleh ratblog, oli Mobil 1 FS 0w40 ini memiliki nilai 127.221psi, dan menduduki rangking nomer 3.

Padahal sesuai artikel diatas, oli ini berbahan dasar GTL. Dan sekali lagi ratblog mementahkan perdebatan ttng mana yg lbh baik antara PAO vs grup3.

Spt yg ratblog tulis, bahwa ” The only thing that matters is the base oil and its additive package “as a whole”, with the primary emphasis being on the additive package, since the additive package is what contains the extreme pressure anti-wear components.” Jd bukan hanya base oli saja yg paling penting. Addtive juga turut andil besar, dalam menentukan oli yg bagus dan berkualitas ato tidaknya. Menurut ane, pernyataan tsb adalah benar adanya.

SukaSuka

terima kasih, iya, mungkin akan makin banyak atau malahan sudah banyak yang pakai GTL.

mungkin perlu dikutip lengkapnya.

Yang di tes adalah “Load carrying capability/film strength/shear resistance”

SukaSuka

Oh ya, satu lagi yg blm di kupas oleh penulis, yaitu, biaya investasi.

Biaya investasi yg dikeluarkan oleh shell pada plant (kilang) GTL ini di Qatar, menghabiskan dana sekitar $18 billion-$19 billion utk development cost.

Biaya investasi real nya bisa melebihi angka tsb diatas.

Itulah sebabnya, harga jual oli dgn base GTL ini msh tergolong tinggi / mahal. Karena ongkos investasi nya sangatlah tinggi, walaupun biaya produksi GTL ini termasuk murah.

http://www.shell.com/about-us/major-projects/pearl-gtl/pearl-gtl-an-overview.html

SukaSuka

Sip, terima kasih, iya tidak kepikiran.

SukaSuka

Itu masang link2 & dasar dr LDIC dah ijin sm pemilik/admin nya dulu blm tuh………

Tolong segera konfirmasi ke LDIC……..

SukaSuka

Sebelum posting list oli, sudah tanya penyusun terlebih dahulu.

SukaSuka

@ penulis & @ batman keblasuk

Sori sebelumnya, agak OOT.

Group FB LDIC msh aktif gak ya? Kok ane cari di FB gak nemu-nemu.

SukaSuka

masih aktif, kalau nggak bisa search ada kemungkinan di ban

SukaSuka

Dari tadi bahas oli melulu, bahas juga teknik cryogenic dan heat treatment pada beberapa sparepart mesin.

SukaSuka

Itu proses produksi ya, menarik juga, pabrik mana yang implementasi teknologi itu ya?

SukaSuka

Itu teknik untuk menguatkan struktur susunan baja pada beberapa sparepart mesin agar tidak cepat rusak di geber pada rpm tinggi. Mungkin hanya ada di dunia balapan.

Nih contoh linknya untuk heat treatment pada camshaft :

https://5osial.com/2010/12/13/warning-heat-treatment-penting-bagi-mesin-yang-dikorektune-up/

SukaSuka

Ok, terima kasih. akan saya coba bahas.

SukaSuka

Kualitas blog ini membahas sebuah fakta ilmiah semakin baik dan baik dari hari ke hari, dan dengan bro Selamat memberikan clue bahasan bahasannya menjadi semakin menarik.

SukaSuka

terima kasih

SukaSuka

Saya mau coba oli fastron gold di motor matic , ??

SukaSuka

Rasanya banyak yang sudah melakukan itu, teruskan saja.

SukaSuka

Mksh pak. Insya Allah, akhir bulan mau coba. Untuk durasi kira2 berpa km ya pak.

SukaSuka

Fastron gold mestinya bisa lebih dari 5000km, tapi sebaiknya di tes juga, karena kan bisa masih kecampuran oli lama yang masih tersisa di mesin. Kalau berkurang harus ditambahi juga.

SukaSuka

Harga kisaran brp pak??

SukaSuka

Sekitar 130-150 rb

SukaSuka

[…] Dari klaim – klaim diatas dikatakan bahwa oli dari bahan PAO itu yang paling bagus lubricity atau film strengthnya. Namun masalahnya, informasi dari pihak akademisi dan pabrikan oli lain membantah hal itu. ala… […]

SukaSuka

[…] Sebelumnya juga pernah membahas bagaimana oli bahan GTL (VHVI) bisa punya film strength lebih baik daripada PAO: – Oli mesin hasil proses Gas to Liquid masuk kategori grup 3 tapi kemampuan mendekati PAO, apa ini ala… […]

SukaSuka

Bahas PAO, VHVI, GTL, TBN, beberapa aditif dan efeknya serta seluk beluk oli sesat dan sejenisnya. Tapi saya belum nemu bahasan berbau “komparasi” antara pelumas produksi baru dan pelumas yang diproduksi dari daur ulang oli bekas. Di Indonesia kan ada tiga merek yang pelumasnya merupakan hasil olahan oli bekas yaitu Evalube, Agip/Eni, sama Pennzoil. Bisa dibuatin artikel tersendiri kangbro ? Kan lumayan memberi sudut pandang baru bagi user awam yang mungkin baca blog ini.

Karena saya punya pengalaman bagus dengan Evalube Runner (single grade dan termurah hingga pernah saya ragukan awalnya). AHM Oil mah lewaaaaaat.

SukaSuka

Terima kasih sharingnya. Iya, akan saya coba kumpulkan infonya.

SukaSuka

Ini artikelnya.

https://kupasmotor.wordpress.com/2017/03/06/oli-mesin-dari-bahan-oli-bekas-pun-kualitasnya-bisa-bagus/

SukaSuka

Boleh dilist bro, oli motor & mobil apa saja yg proses pembuatannya sudah menggunakan GTL?

SukaSuka

Sayangnya yang beginian tidak di share. Kemungkinan kebanyakan VHVI sekarang pakai GTL. Yang pasti adalah castrol dan shell.

Daftar oli mesin PCMO, HDEO dan MCO yang cocok atau tidak cocok untuk kopling basah beserta informasi base oilnya

SukaSuka

Castrol yg prosesnya sudah GTL untuk tipe apa saja ya pak?

SukaSuka

castrol edge mestinya GTL. sementara magnatec campuran GTL dan grup II.

SukaSuka

[…] Di sisi pabrikan jadi bisa ganti resep seenaknya. Karena di bungkus nggak ada tulisan PAOnya. Apalagi dari sisi sifatnya, oli mineral pun bisa dibikin mendekati sifat oli PAO: Oli mesin hasil proses Gas to Liquid masuk kategori grup 3 tapi kemampuan mendekati PAO, apa ini ala… […]

SukaSuka